Business / Global

Outside the box

It may now be standard to refuse a plastic bag at the supermarket, but with e-commerce on the rise, that’s only the tip of the iceberg when it comes to the problems caused by the disposable packaging industry. We meet the people with solutions.

Online shopping means the packaging market is exploding: it was worth about $870bn in 2017 and is predicted to reach $1trn by 2023. But what about the eco-credentials of all the boxes, bags and stuffing accompanying all those purchases? And can companies still communicate their brand’s values while being more sustainable? From mushroom moulds to intelligent boxes, we look at how people from across the board are rising to meet the challenge.

1.

The big player

Boxing clever

We’re at the Stora Enso packaging factory in the Finnish town of Lahti. The Swiss-made Masterflex flexographic printing-press huffs and puffs as a steady flow of brown corrugated board is fed into the machine. It cuts it into shape and prints the customer’s brand identity on it in colourful high-definition, before spitting it out again. A package is born.

“When I joined 11 years ago I could not have imagined that one day we would achieve this precision and print quality,” says production manager Roope Laaksonen, inspecting the final product. That’s not the only change that he has witnessed: Nordic paper companies such as Stora Enso were among the largest in the world until digitalisation forced them to rethink their strategy. In a region where much of the land is covered in forest, a renewable and ecological source of raw materials, packaging was the solution.

Leading the charge is Stora Enso. The Finnish-Swedish paper behemoth employs 26,000 people in 30 countries worldwide and had a 2018 turnover of €10.5bn. The Lahti factory is now one of the largest packaging factories in the world, churning out 230 million products a year. The amount of cardboard shipped out of the factory in one day would be enough to cover the road from Brussels to Amsterdam.

“A decade or so ago, 70 per cent of turnover came from paper but it accounts for less than 30 per cent now; packaging has grown from 28 per cent to about 40 per cent,” says Vesa Penttinen, business-development manager for the company’s packaging division. Key to this growth is the firm’s push towards more innovation in sustainability. Its product line, for example, includes wood-based biocomposites that can replace plastics in cosmetics packaging and be used for renewable and recyclable leak-tight packaging for the food industry. Items designed specifically for e-commerce feature easy resealing for hassle-free returns.

Yet pleasing its clients has required a tricky balancing act: as well as being functional and cost-efficient, packaging also needs to look good. Up on the factory’s second floor, designer Outi Honkavaara is busy working out this conundrum for a box that will contain plant seedlings. “Our customers want the packaging to reflect their brand more than ever before,” she says.

Sustainable packaging is not just about the right materials or recycling after use. It is also about ensuring maximum efficiency and reducing waste, particularly when it comes to perishable goods. “Soon our packages will be able to sensor what is inside, what the temperature is and how much oxygen there is,” explains Juha Maijala, deputy head of intelligent packaging at the company’s innovation centre in Helsinki. “Just think about what this can achieve, for instance, in the food industry.”

2.

The specialists

Bio-packaging

In 2007, Eben Bayer and Gavin McIntyre started a company based on something most people wouldn’t think twice about, something hidden under woodpiles and on tree trunks: mycelium. It’s a living organism comprising the cobweb-like roots of fungi that, when combined with agricultural byproducts such as woodchips or cornstalks, can be grown into a durable, fully biodegradable material. It can then be used for any shape desired, from packaging for a wine bottle to protective corners for a TV. “It’s able to perform like a plastic during its life cycle,” says Bayer. “But then it actually breaks down and can be returned to the earth as a nutrient.”

Today Ecovative Design, which is based in Green Island, New York, is capable of producing 900,000kg of mycelium per year. Customers include Ikea, Dell, and New York-based lighting firm Rich Brilliant Willing. Such eco-friendly products were once too expensive for upstart brands but today they are cost competitive; the firm was able to make custom packaging for direct-to-consumer probiotic firm Seed Health, despite a modest first order. “The brand is about sustainability so our packaging helps them tell a story that they feel strongly about: protecting both your body and the Earth,” says Bayer.

Green packaging hasn’t always made a hot sales pitch. In 1997, Tim Colonnese founded ktm Industries, a Michigan-based manufacturer of what he called Green Cell Foam: a Styrofoam replacement made of cornstarch for cushioning fragile items. The product is water-soluble so it can be poured down the drain; it also requires 70 per cent less energy to produce and creates 80 per cent less greenhouse gas than conventional foams. The product was released to market in 2002. “All we heard were crickets,” says Colonnese.

By 2010, KTM was on the cusp of bankruptcy. Then, due to a combination of clever business decisions and sustainability rising on the consumer agenda, things started picking up. “Now corporations are hopping on the bandwagon, saying, ‘We’re getting lots of blowback from our customers and shareholders – we need to be doing better things for the environment,’” says Colonnese. He expects 50 per cent growth in sales in 2020 and again in 2021. “We have yet to scratch the surface,” says Colonnese. “If we can make this locally available in more markets – in North America, Europe, Australia – this could be a billion-dollar company.”

Both Bayer and Colonnese are working on minimising their carbon footprint. Ecovative Design is licensing its technology to entrepreneurs, while ktm is opening a manufacturing facility on the West Coast of the US to avoid long shipping distances and meet growing demand. “It’s been a long time coming,” says Colonnese. “I’ve been at this for 22 years and thank God we stuck around, because now people are truly interested in what we’re doing.”

3.

The industry approach

Experiential unboxing

Fashion pollutes. It’s the second-most environmentally destructive industry (oil holds firm at number one). In response, sustainability has become an industry buzzword. Labels such as Raeburn, Stella McCartney and Gabriela Hearst are known for their upcycled, eco-friendly materials and it’s now easy to get a thoughtfully produced coat and learn the origin of every fibre. Buy it online, however, and you’ll know almost nothing about the packaging it comes in – beyond the fact that some of it is single-use plastic and a lot of it appears unnecessary.

As a result it seems packaging lags behind in terms of sustainability – but the reality is more complicated. Take polybags: those thin plastic bags wrapped around individual items of clothing. The challenge of packaging in fashion extends far beyond them but they illustrate the scale and nature of the problem.

The ubiquity of polybags isn’t just due to laziness; the clothing industry has spent a lot of time and money trying to find alternatives. Patagonia, which puts millions of dollars into environmental action, decided it couldn’t stop using polybags after testing showed that without them, 30 per cent of goods were damaged before they left the factory. Everlane, a US online clothing company whose slogan is “radical transparency”, has committed to removing virgin plastic from its supply chain by 2021: it spent months looking for alternatives to polybags. In the end the best it could do was replace virgin plastic bags with recycled ones. “A garment that’s damaged and can’t be used has a significant footprint as well,” says Bleue Wickham-Burnham, head of sustainability at UK menswear brand Oliver Spencer. “That’s the thing about sustainability: there’s no straightforward answer.”

Wickham-Burnham has spent a lot of time investigating polybag alternatives. Part of the issue is that, surprisingly, plastic packaging can require three times less energy and emit less greenhouse gas in production than alternatives such as cardboard. “We’ve talked with recycled paper suppliers but from a carbon perspective, plastic is still the lowest-footprint material at the moment,” he says.

Many of the materials that consumers feel good about are less environmentally effective than they seem: the cotton tote’s carbon footprint, for example, is 131 times higher than that of a single-use plastic bag. Bioplastics – derived from natural materials – are better than standard plastic from a carbon standpoint, according to a University of Pittsburgh study, but deplete more of the ozone and require extensive land use.

Even when everything is designed to have a second life it can still be problematic. High-end online retailer Net-a-Porter now boasts a long list of packaging that is recyclable or biodegradable, including boxes, ribbons, tissue paper, garment-protection bags and shoe dust bags. Yet that’s still a lot to manufacture and it will quickly be thrown out.

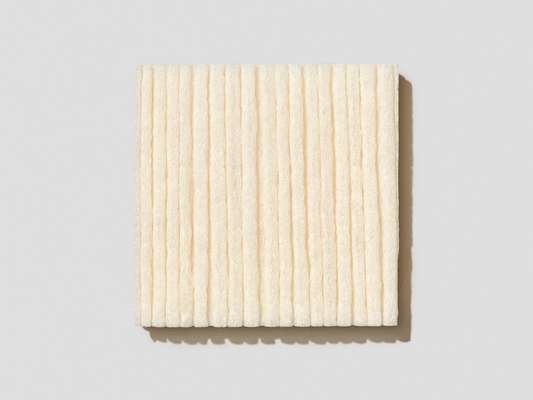

The most effective solution is no doubt the least technical: just use less. Wickham-Burnham says, “The first thing we did, before even looking at the fabrication of our clothes, was remove all the innards from our shirts: the cardboard, rice paper and plastic in the collar. Now they’re just beautifully folded. That’s reduced our annual carbon footprint by 36,000kg. The new luxury comes from innovation and ideas – that’s what people find interesting.”

Have there been customer complaints? “Not one,” says Oliver Spencer himself. “And let’s say Matches or Mr Porter sends a garment to a customer – he unpacks it, doesn’t like it and sends it back. Well, it has to be repackaged again with all that stuff. Now that’s not necessary.”

Yet it’s a dilemma for an industry where a certain quality of packaging has traditionally been part of how luxury brands advertise their value and add to the ceremony of the transaction. People who buy cleaning products on Amazon don’t talk about “the unboxing experience”; fashion customers do.

London-based luxury retailer Matches Fashion, for example, has an “eco” packaging option but still offers its signature marble boxes, which are celebrated across social media. The rationale? “Customers expect an experience that reflects the quality and style of the pieces they’ve purchased,” says Jess Christie, chief brand officer. While the company is aware younger customers are “increasingly looking to retailers to support them in reducing their environmental footprints”, she says, it also needs to cater to older people’s expectations.

Not everyone agrees. “Our customers’ relationship to packaging, and to all things ecological, has undergone a notable change,” says Tim Sayler, chief marketing officer at watchmaker Breitling. “Some want only the pouch and others want the watch without anything at all.”

It’s comforting, and partially justified, to blame giant corporations for polluting the Earth. But when it comes to packaging, we as consumers are a big part of the problem. About 30 per cent of goods bought online are sent back. And each time we buy something in three sizes and return two or have something sent out instead of going to a shop, we’re adding to that item’s carbon footprint. For fashion to stop being one of the most polluting industries, people will have to shop differently and reassess the sustainability of eco-friendly clothing packaged in a way that undermines the product itself. Consumers will have to decide that, when it comes to fashion and packaging, it’s what’s inside that counts.